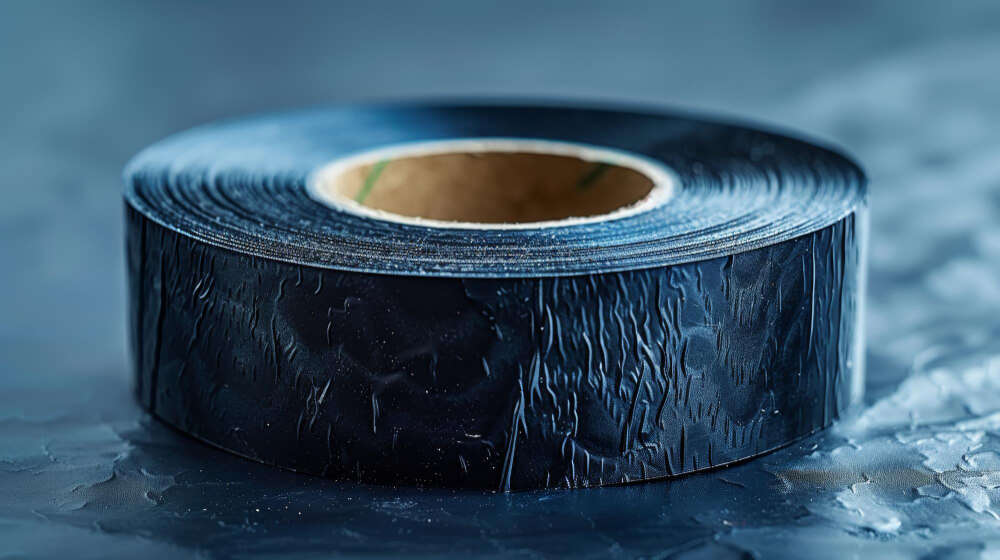

Water activated casting tape has quickly become the preferred solution in the medical and orthopedic industry for creating secure, long-lasting casts. Designed to harden rapidly when exposed to water, it provides exceptional rigidity, breathability, and comfort compared to traditional plaster bandages. For hospitals, urgent care clinics, physiotherapists, sports medicine professionals, and veterinary practices, water activated casting tape is now the gold standard.

Whether you’re immobilising a fracture, supporting an injured limb, or crafting specialised orthopedic structures, this tape delivers performance, speed, and reliability every single time.

What Is Water Activated Casting Tape?

Water activated casting tape is a lightweight fiberglass or polyester-based casting material coated with a polyurethane resin. Once dipped in water, the resin activates, and the material becomes moldable for a short period. It then hardens into a rigid, durable cast.

This technology offers several advantages over traditional plaster casts:

• significantly lighter

• stronger and more durable

• water-resistant

• better airflow and comfort

• faster setting time

• less bulky

Because of these benefits, medical professionals rely on water activated casting tape when precision and patient comfort are top priorities.

Why Water Activated Casting Tape is a Superior Casting Solution

1. Fast Setting for Quick Procedures

Once activated, the tape begins curing within minutes.

This reduces patient waiting time and increases treatment efficiency.

2. Lightweight Yet High Strength

While lighter than plaster, water activated casting tape offers exceptional rigidity and support perfect for high-mobility patients.

3. Breathable and Comfortable

The open-weave structure promotes airflow, reducing skin irritation and moisture buildup.

4. Excellent Molding Capabilities

Clinicians can easily shape the tape around anatomical structures for a customised fit.

5. Water Resistance

This is a huge relief for active patients and children.

It can withstand light moisture far better than plaster casts.

6. Reduced Breakage

Fiberglass-based tapes maintain integrity even under pressure, making them ideal for long-term immobilisation.

7. Cleaner & Easier Application

No plaster dust, no mess just clean handling with professional results.

How Water Activated Casting Tape Works

The operation is incredibly simple but highly effective:

Step 1: Prepare the Area

Apply appropriate padding or stockinette on the patient’s limb.

Step 2: Activate with Water

Dip the roll into room-temperature water for 3–5 seconds.

This activates the polyurethane resin.

Step 3: Apply and Mold

Wrap the tape smoothly around the limb and shape it as needed.

Step 4: Allow to Cure

It typically hardens within 3–7 minutes depending on brand and water temperature.

The result is a strong, smooth, durable cast that supports proper healing.

Best Applications for Water Activated Casting Tape

This tape is widely used across multiple medical and veterinary environments.

Orthopedic Clinics

Fractures, ligament injuries, stabilisation, and corrective positioning.

Sports Medical Centres

Fast emergency immobilisation for athletes.

Hospitals & Emergency Departments

Reliable support for trauma patients requiring immediate stabilisation.

Physiotherapy & Rehabilitation

Lightweight casts and splints that encourage healing while maintaining mobility where needed.

Veterinary Use

Perfect for animal limb support stronger and safer than plaster.

Water Activated Casting Tape vs Plaster Casts

| Feature | Water Activated Casting Tape | Plaster Cast |

|---|---|---|

| Weight | Very light | Heavy |

| Strength | High | Moderate |

| Setting Time | Fast | Slow |

| Cleanliness | Clean | Messy |

| Breathability | Excellent | Limited |

| Moisture Resistance | Good | Poor |

| Patient Comfort | High | Medium |

For modern healthcare providers, the performance difference is clear.

Tips for Best Results

• Always use gloves when handling the tape

• Avoid excessively warm water, which reduces working time

• Smooth each layer to avoid bubbles or weak spots

• Use proper padding to enhance patient comfort

• Keep materials organised for faster application in emergencies

Following these steps ensures consistent, professional casting results.

Safety & Precautions

While water activated casting tape is safe and widely used, professionals should:

• avoid skin contact with resin before setting

• prevent excessive tightness during application

• monitor circulation and sensation post-application

• educate the patient about cast care

Proper technique ensures optimal healing and patient satisfaction.

Sustainability & Material Considerations

While most fiberglass options are not biodegradable, many clinics are shifting toward polyester water activated casting tapes, which offer a balance between performance and sustainability. If your clinic prioritises eco-responsible supplies, explore more sustainable packaging and materials options here:

https://carewellgroup.com.au/sustainability/

Internal Links (Carewell Group)

Packaging supplies for clinics & medical logistics:

https://carewellgroup.com.au/product-category/packaging/

Fiberglass tapes and industrial tapes:

https://carewellgroup.com.au/product-category/tapes/

Tools & equipment:

https://carewellgroup.com.au/product-category/tools-equipments/

Custom solutions for medical & industrial clients:

https://carewellgroup.com.au/custom-solutions/

Explore our main site:

https://carewellgroup.com.au/

Clear Headline

Premium Water Activated Casting Tape for Professional Medical & Orthopedic Use

Subheading

Designed for fast setting, superior strength, and comfortable immobilisation across medical, emergency, sports, and veterinary applications.

Location & Contact

Carewell Group Pty Ltd

Unit 27/191, Mccredie Road, Smithfield, NSW 2164

Phone: +61 0477 123 699

Email: sales@carewellgroup.com.au | info@carewellgroup.com.au | logistics@carewellgroup.com.au