AI Overview

Efficient and precise garment assembly is essential in apparel production. Choosing the right adhesive—whether double-sided tape for fabric or fabric glue—can affect production speed, seam strength, and overall garment quality. This blog examines the differences between these adhesives, their applications, and how low-temp bonding options enhance efficiency in modern apparel manufacturing.

Why Choosing the Right Adhesive Matters

- Production Efficiency: Reduces assembly time and labor costs.

- Garment Integrity: Ensures seams and embellishments remain secure during wear and washing.

- Material Compatibility: Some fabrics require gentle adhesives to prevent damage or staining.

- Sustainability: Eco-friendly adhesives reduce chemical usage and waste.

Selecting the wrong adhesive can lead to weak bonds, fabric damage, or slower production times.

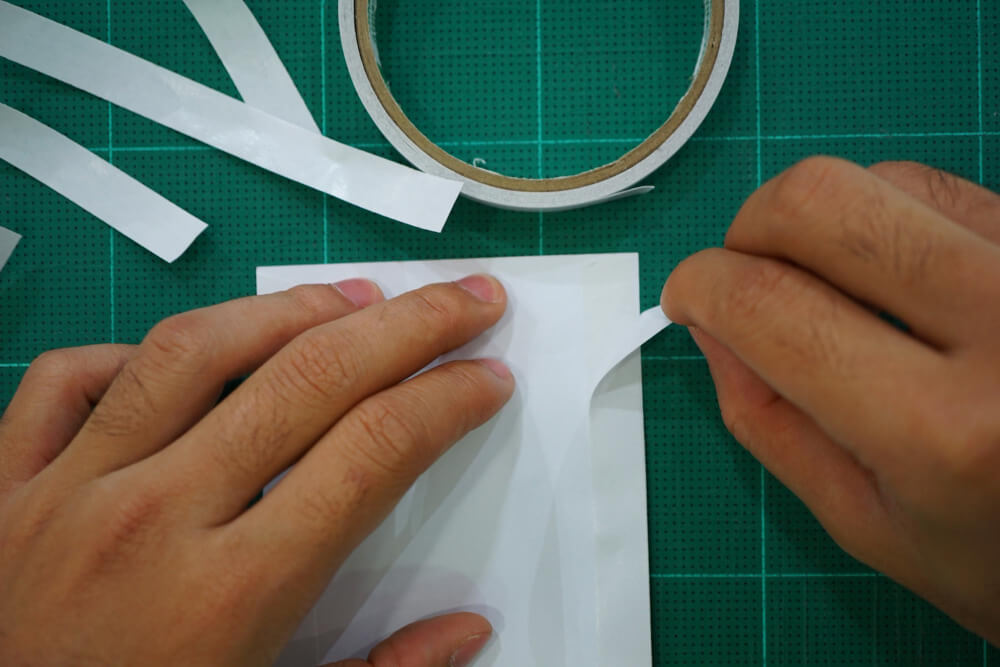

Double-Sided Tape for Fabric

Features & Benefits

- Clean & Quick Application: Ideal for temporary holds or pre-assembly alignment.

- Low-Temp Bonding: Works without heat, protecting delicate fabrics like silk or chiffon.

- Versatile Uses: Hemming, applique placement, interfacing, and seam stabilization.

- Minimal Mess: No drying time or chemical residue compared to liquid adhesives.

Double-sided tape for fabric is particularly useful in fast-paced manufacturing environments where precision and speed are critical.

Fabric Glue

Features & Benefits

- Permanent Bonding: Provides a strong hold for embellishments, patches, and hems.

- Flexible & Washable: Some formulations are machine-wash safe, making them suitable for finished garments.

- Variety of Formulations: Options include solvent-based, water-based, and low-temperature adhesives.

- Ideal for Decorative Applications: Effective for embroidery, appliques, and specialty fabrics.

Fabric glue is a go-to option for projects that require permanent adhesion but may be slower to apply and require drying time.

Comparing Double-Sided Tape and Fabric Glue

| Feature | Double-Sided Tape for Fabric | Fabric Glue |

|---|---|---|

| Bond Type | Temporary or semi-permanent | Permanent |

| Application Speed | Fast, instant adhesion | Slower, drying time required |

| Low-Temp Bonding | Excellent | Depends on formulation |

| Mess & Residue | Minimal | Potential for residue or staining |

| Best For | Alignment, hemming, temporary hold | Permanent attachment, decorative applications |

| Washability | Temporary; may not survive washing | Often washable depending on formula |

Key Insight: Double-sided tape excels in speed, precision, and low-temp applications, while fabric glue provides a stronger permanent bond, ideal for durable finishes.

Internal Link: Double-Sided Tape for Fabric vs Fabric Glue

Why Apparel Manufacturers Choose Carewell Solutions

Carewell Group provides high-quality garment assembly adhesive solutions tailored to apparel production:

- Double-Sided Tape for Fabric: Reliable temporary adhesion for alignment, hemming, and lightweight fabrics.

- Fabric Glue Options: Strong, washable adhesives for permanent decorative and functional applications.

- Low-Temp Bonding Expertise: Protects delicate textiles while maintaining efficiency.

- Consultation & Custom Solutions: Assistance in choosing the right adhesive for specific materials and production needs.

Benefits of Using the Right Adhesive

- Faster Assembly: Reduce manual adjustments and rework.

- Improved Garment Quality: Ensure seams, hems, and embellishments are secure.

- Reduced Waste: Avoid damage or fabric rejection due to improper adhesion.

- Versatile Applications: Suitable for fashion, sportswear, uniforms, and home textiles.

- Operational Efficiency: Streamline production and maintain consistency across batches.

Contact Carewell Group Today

Phone: +61 0477 123 699

Email: sales@carewellgroup.com.au | info@carewellgroup.com.au | logistics@carewellgroup.com.au

Address: Carewell Group Pty Ltd, Unit 27/191, McCredie Road, Smithfield, NSW 2164

External DoFollow Resources: